Why Choose AITOP Battery Pack Assembly Line

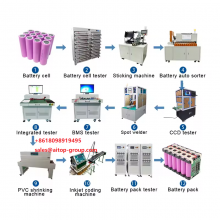

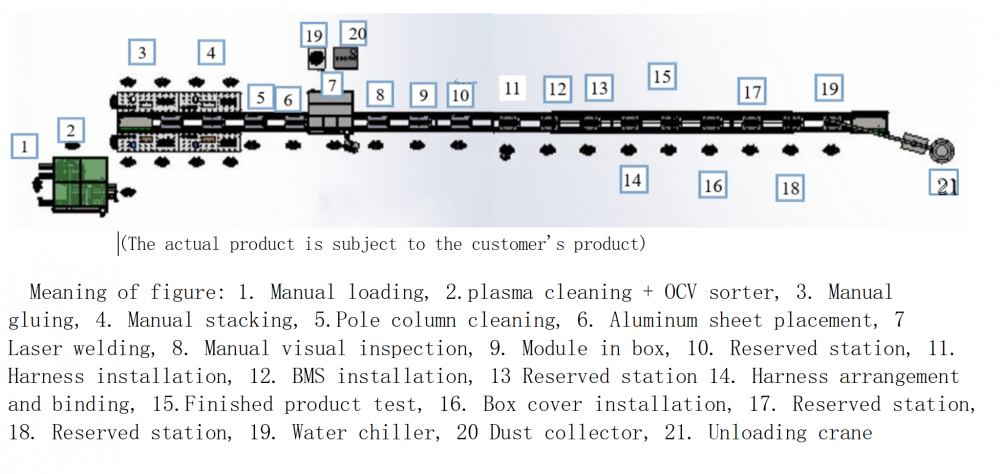

AITOP Automatic Prismatic Lithium Ion Battery Pack Assembly Production Line For Energy Storage System complete the sorting, welding, testing and assembly functions of prismatic lithium battery modules. The line includes: manual loading, automatic code scanning, OCV testing, automatic NG discharge, battery cell cache, manual stacking and bundling, manual module handling into boxes, manual code scanning & labeling, polarity detection & terminal addressing, terminal laser cleaning, manual connection piece placement, laser welding, EOL testing, cantilever module transfer, manual pack assembly, hoisting off the line, pack tooling tray manual lifting car reflow assembly process. Data collection at each station, reserved port upload to connect to MES system

QUALITY ASSURANCE

One-year warranty and lifetime maintenance, with overseas technical support.

GOOD SERVICE

Professional team full of enthusiasm and sense of responsibility, and consider creating value for customers as the first priority.

REASONABLE PRICE

We have three factories covering over 20,000 square meters, providing great production capacity.

FAST DELIVERY

Rich export experience in more than 50 countries. Have implemented more than 60 complete solution projects for lithium-ion battery and battery pack production equipment.

Comprehensive and Integrated Process Coverage

High Degree of Automation with Human-Machine Collaboration Optimization

Multi-Dimensional Quality Control System

Intelligent Data Management and MES Connectivity

Improve Production Efficiency of Energy Storage Battery Packs

Guarantee the Safety and Reliability of Energy Storage Systems

Promote the Intelligent Upgrade of the Energy Storage Manufacturing Industry

Support the Large-Scale Development of the Energy Storage Industry

We provide all kind of lithium battery pack assembly machines and solutions with good quality and services.

Our products including:

1.IR tester

2.Capacity tester for cylindrical &prismatic&polymer cells

3.BMS tester

4.Sorting machine for common use

5.Insulation paper sticker machine

6.Manual spot welding machine

7.Automatic spot welding machine

8.Battery pack integrated tester

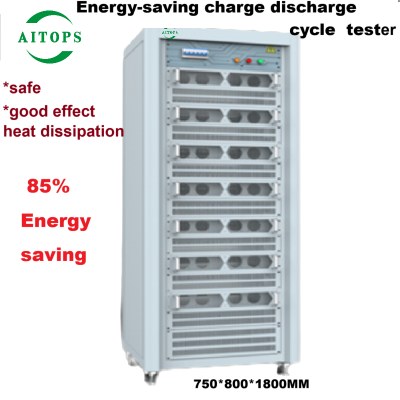

9.Battery pack charging discharging aging machine

10.PVC shrinking machine

11. Nickel plate&PVC cutting machine

12.Laser welding machine

13.Wire bonding machine and etc.

All of our products are good price.

If you have any interesting,please feel free to contact with us

TOP Battery machine factory contact number

Shenzhen AITOP Intelligent Equipment Co., Ltd.

Email :sales(@)aitop-group.com /leon(@)aitop-group.com

wehcat/whatsapp /Phone :+8618098919495

sales.aitopgroup@gmail.com

Recently Posted

-

Which is the necessary materials and machine for assembly drone battery pack from AITOP group

December 17, 2025Which is the necessary materials and machine for assembly drone battery pack from AITOP groupThe main equipment of cylindrical lit Read More

Read More -

AITOP | High-Efficiency Battery Pack Assembly Lines for E2W & E3W Vehicles &drone battery

December 17, 2025AITOP | High-Efficiency Battery Pack Assembly Lines for E2W & E3W VehiclesPower the electric mobility revolution with precisio Read More

Read More -

21700 18650 32650 Lithium Ion Battery Pack Assembly Line

October 8, 2025Lithium Ion Battery Pack Assembly LineProducts Description Lithium ion Battery Pack Assembly Line is mainly to process batter Read More

Read More -

Automatic ESS Prismatic Lithium Battery Pack Assembly Line

October 8, 2025Automatic Prismatic Lithium Battery Pack Assembly Lineproduction process requirements and workshop layout, custom-made combined sq Read More

Read More