In the booming global UAV market—where consumer drones capture stunning aerial views, agricultural drones boost crop yields, and industrial drones execute precision inspections—one component stands as the backbone of reliable performance: the battery pack. A UAV’s flight time, load capacity, and operational safety hinge entirely on its battery, making consistent production quality and stable performance non-negotiable. To meet these critical demands, manufacturers turn to

AITOP’s UAV Drone Battery Pack Assembly Line—a suite of specialized equipment engineered to safeguard every stage of battery production.

The Indispensable Role of UAV Drone Batteries: Why Quality Cannot Be Compromised

For UAVs, batteries are more than just power sources—they are mission-critical systems. A consumer drone’s 20-minute flight window depends on battery energy density; an agricultural drone’s ability to cover 100 acres per charge relies on stable discharge; a search-and-rescue drone’s reliability in harsh weather hinges on robust safety design.

Poor-quality batteries spell disaster: inconsistent cell matching cuts flight time by 30% or more; shoddy welding leads to sudden power failures mid-flight; inadequate insulation triggers short circuits and even thermal runaway. In industries where UAVs replace human labor in high-risk environments, battery failures don’t just mean product returns—they risk equipment loss, project delays, or even safety hazards.

This is why UAV manufacturers, from startups to industry leaders, prioritize battery production lines that merge efficiency with uncompromising quality control. AITOP’s equipment suite is built to address this exact need.

AITOP’s Equipment Suite: The Backbone of Reliable UAV Battery Production

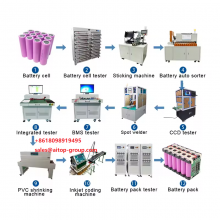

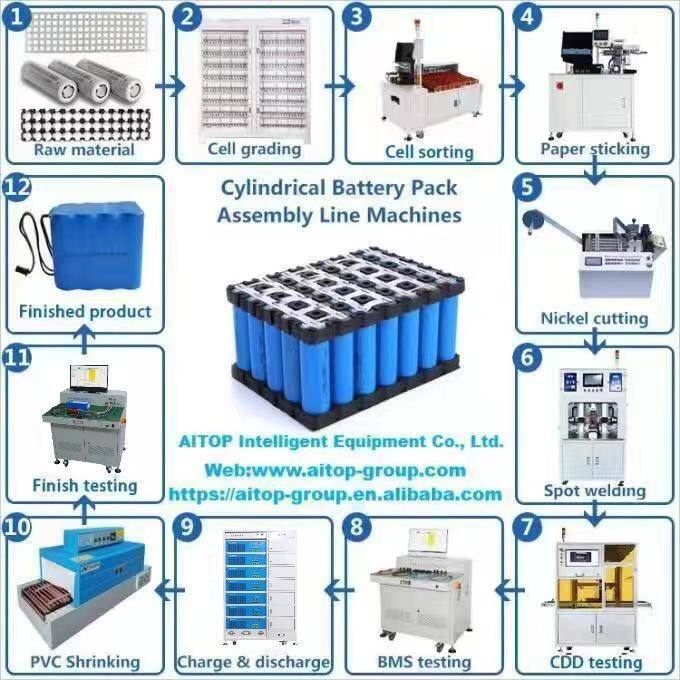

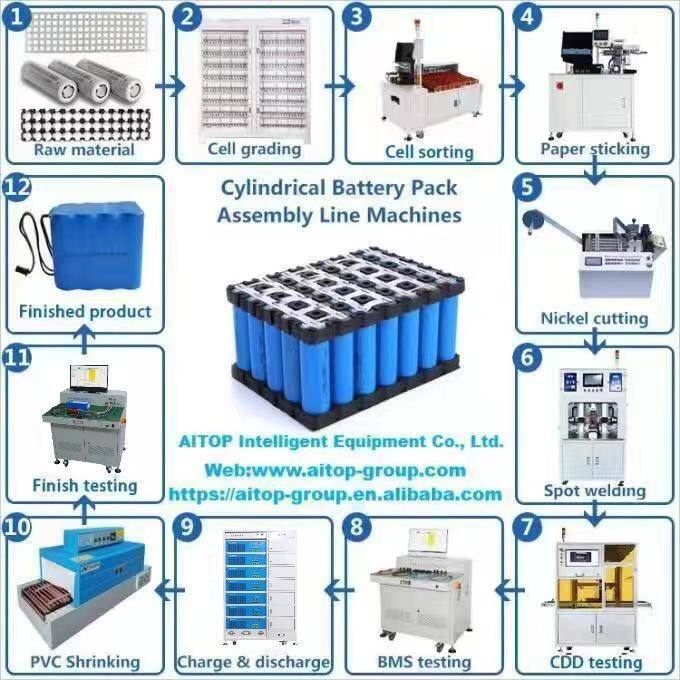

Every piece of AITOP equipment is tailored to the unique challenges of UAV battery manufacturing, from cell screening to finished product verification. Here’s how each component ensures production efficiency and quality excellence:

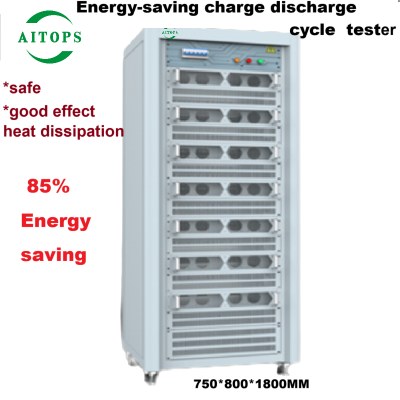

1. Battery Charge-Discharge Testers: Screening for Consistent Performance

AITOP’s 256/512 Channels Battery Testers (5V, optional 3A/5A/6A/10A) and high-current Cell Charge-Discharge Testers (5V, 3A-200A) are the first line of defense. They simulate hundreds of charge-discharge cycles to weed out cells with capacity decay or voltage instability—critical for UAVs that need consistent power output. For finished packs, AITOP’s Battery Pack Charging-Discharging Aging Machines (10V20A to 120V60A) subject products to real-world load conditions, ensuring they maintain performance over time.

2. Precision Assembly Tools: Building for Compact, Lightweight Design

UAV batteries demand miniaturization without sacrificing safety. AITOP’s Battery Insulation Paper Sticking Machine applies precision-cut insulation materials to fit tight cylindrical battery layouts, eliminating weight redundancy while preventing short circuits. The Automatic Cylindrical Battery PVC Heat Shrink Wrapping Machine adds a thin, durable protective layer that keeps batteries lightweight yet resistant to vibration—perfect for drones navigating turbulent air.

3. Intelligent Sorting & Inspection: Eliminating Defects Before Assembly

Mismatched cells are a top cause of UAV battery failure. AITOP’s Battery Sorting Machine classifies cells by voltage, internal resistance, and capacity, ensuring consistent matching that extends flight time by 10–20%. Complementing this, the CCD Visual Inspection Machine uses advanced imaging to detect microscopic flaws: scratches on cell surfaces, misaligned insulation paper, or faulty welding points. It even includes cylindrical battery positive/negative detection to avoid reverse-connection risks.

4. Versatile Welding Solutions: Ensuring Strong, Reliable Connections

Welding quality directly impacts battery conductivity and safety. AITOP offers a full range of options: Manual Spot Welding Machines for flexible small-batch production, Single/Double Sides Automatic Spot Welding Machines for high-throughput assembly, and 1kW Fiber Laser Welding Machines for lithium-ion batteries—delivering precise, high-strength welds that withstand the rigors of UAV flight.

5. Comprehensive BMS & Integrated Testing: Safeguarding Operational Safety

The Battery Management System (BMS) is a UAV battery’s “brain,” and AITOP’s BMS Tester (supports 1-24 series, 1-32 series, 48s) verifies its every function. It tests over-discharge protection (0-120A), overcharge protection (0-50A), and voltage thresholds (0.5-5V) to ensure the BMS triggers safeguards in emergencies. For finished packs, the Battery Integrated Tester (100V120A to 100V500A) conducts all-in-one performance checks, from capacity to insulation resistance.

6. Traceability & Compliance Tools: Meeting Global Standards

AITOP’s Expiry Date and Batch Number Printing Machine marks each battery with unique identifiers, enabling full traceability from raw materials to end-users—essential for after-sales support and recall management. Combined with compliance-ready packaging from the heat shrink machine, this ensures batteries meet global standards like UN 38.3 for aviation and logistics.

Choose AITOP: Partner for UAV Battery Excellence

As a leading manufacturer and supplier of UAV drone battery pack assembly lines in China, AITOP doesn’t just provide equipment—it delivers a quality assurance ecosystem. From high-throughput cell testing to precision welding and intelligent inspection, every tool is designed to solve the UAV industry’s most pressing battery challenges.

For UAV manufacturers aiming to build reliable, high-performance products, AITOP’s equipment isn’t an option—it’s a necessity. Because when it comes to UAV batteries, quality isn’t just about meeting standards—it’s about powering missions that matter.

TOP Battery machine factory contact number

Shenzhen AITOP Intelligent Equipment Co., Ltd.

Email :sales(@)aitop-group.com /leon(@)aitop-group.com

sales.aitopgroup@gmail.com

UAV Drone Battery Pack Assembly Line-UAV Unmanned Aerial Vehicle Drone Battery Pack Assembly Line.UAV (Unmanned Aerial Vehicle) drone battery pack assembly line is specifically designed for the manufacturing of battery packs used in drones or unmanned aerial vehicles. The assembly line for UAV drone battery pack modules encompasses various stages and processes aimed at efficiently assembling and testing these battery packs to ensure they meet performance, safety, and quality standards. 1,Battery charge discharge tester 256/512 Channels Battery Tester 5V 3A/5A/6A/10a Battery Tester optional ,2. Battery insulation paper sticking machine, 3.Battery sorting machine,4.CCD visual inspection machine, CCD tester Machine Cylindrical battery positive and negative detection 5.Battery pack spot welding machine,Manual Spot Welding Machine , Single Side Automatic Spot Welding Machine Double Sides Spot Welding Machine ,6.BMS tester,1-24 series/1-32 series 48s BMS Tester Over-discharge Protection Current:0-120A Overcharge Protection Current:0-50A Overcharge/Overdischarge Voltage:0.5-5V 7.Battery integrated tester, 100V 120A 200a 300a 500a Battery Pack Comprehensive Tester 8.Heat shrink wrap machine, Automatic Cylindrical Battery PVC Heat Shrink Wrapping packing Machine 9.Expiry date and batch number printing machine,10.Battery pack aging machine attery pack charging discharging aging machine battery pack charge discharge tester 10v20a15v20a,20v20a,30v50a,60v50a,70v20a,100v30a,120v60a capacity tester cell charge discharge tester 5v,3A/6A/10A/20A/30A/50A/60A/100A/200A ,Hot Tags: uav drone battery pack assembly line, China uav drone battery pack assembly line manufacturers, suppliers1kw fber laser welding machine, lithium ion battery welding machine, automatic heat shrink machine, spot weldingmachine for battery, battery cell formation equipment, laser welding machine for lithium ion batteries

Read More

Read More Read More

Read More Read More

Read More Read More

Read More