A Beginner's Guide to Lithium Battery Spot Welders vs. AC Spot Welders: Principles, Applications, and Performance Differences – For Choosing AITOP Lithium Battery Equipment

For beginners venturing into lithium battery assembly and maintenance, selecting the right spot welding equipment is critical to ensuring work efficiency, weld quality, and safety. AITOP, as a provider of lithium battery equipment, offers solutions tailored to different user needs—but first, understanding the core differences between lithium battery storage spot welders (often DC inverter spot welders) and traditional AC spot welders is essential. This guide breaks down their principles, applications, and performance to help you make an informed choice.

1. Core Working Principles: Why They Differ Fundamentally

The core of spot welding lies in concentrating high current on a small contact area to generate instant heat, melting metal surfaces, and forming a weld nugget as the current stops. However, lithium battery spot welders and AC spot welders differ drastically in how they generate and control this current.

1.1 Lithium Battery Storage Spot Welder (DC Inverter Type)

This is a modern, specialized device optimized for lithium battery welding. Its working process involves 4 key steps:

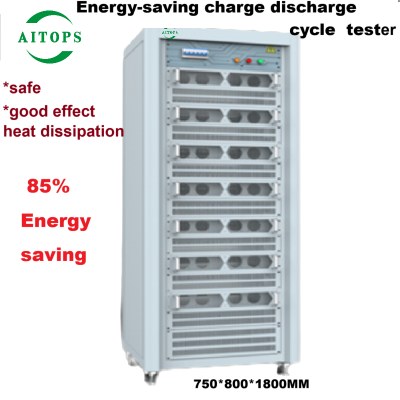

Energy Storage: It uses a built-in lithium battery pack or capacitor bank to store electrical energy (converted from AC mains via a rectifier and inverter).

Inversion & Boosting: The stored DC power is inverted into high-frequency AC, then boosted to the voltage required for welding through a transformer.

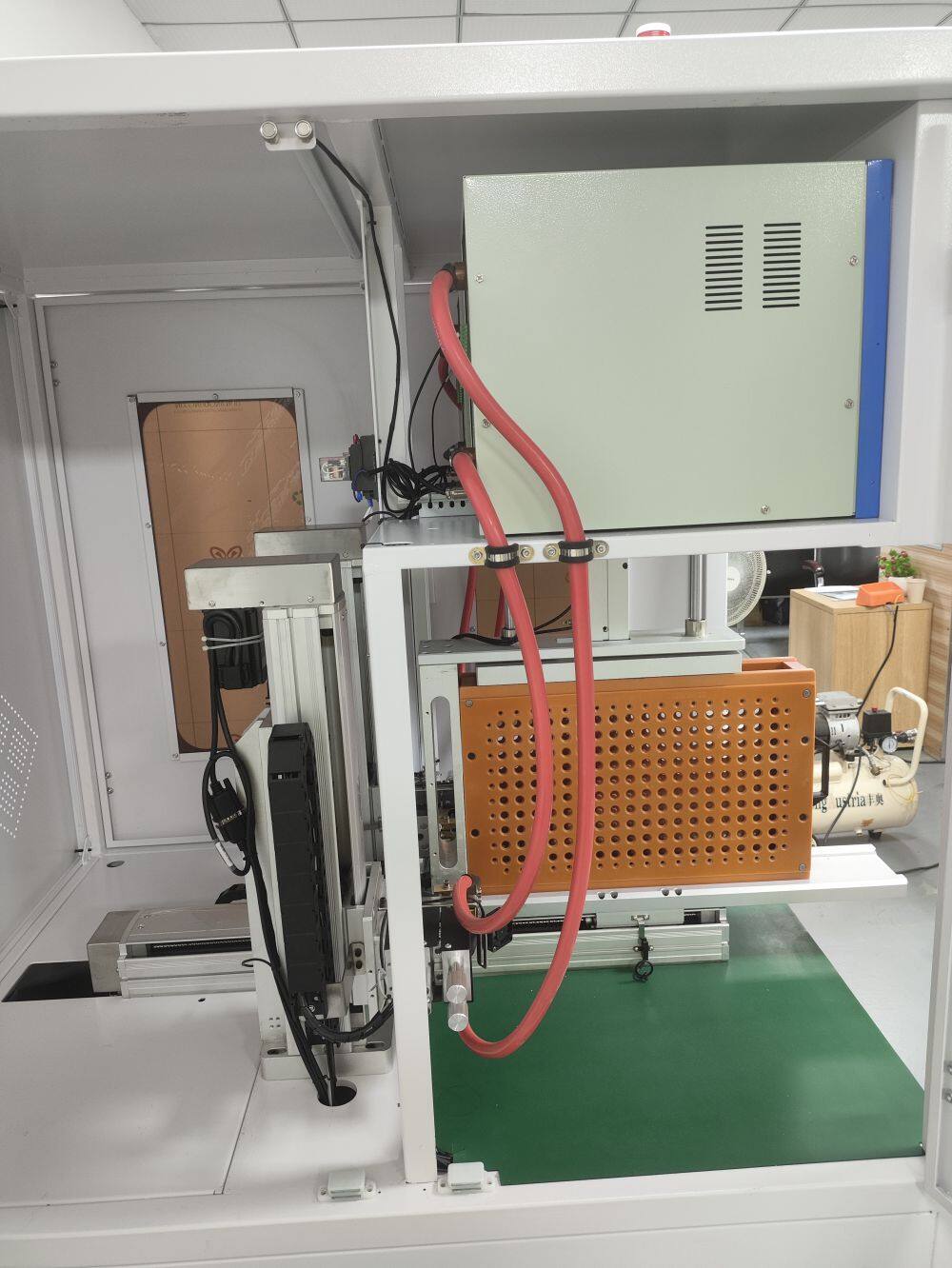

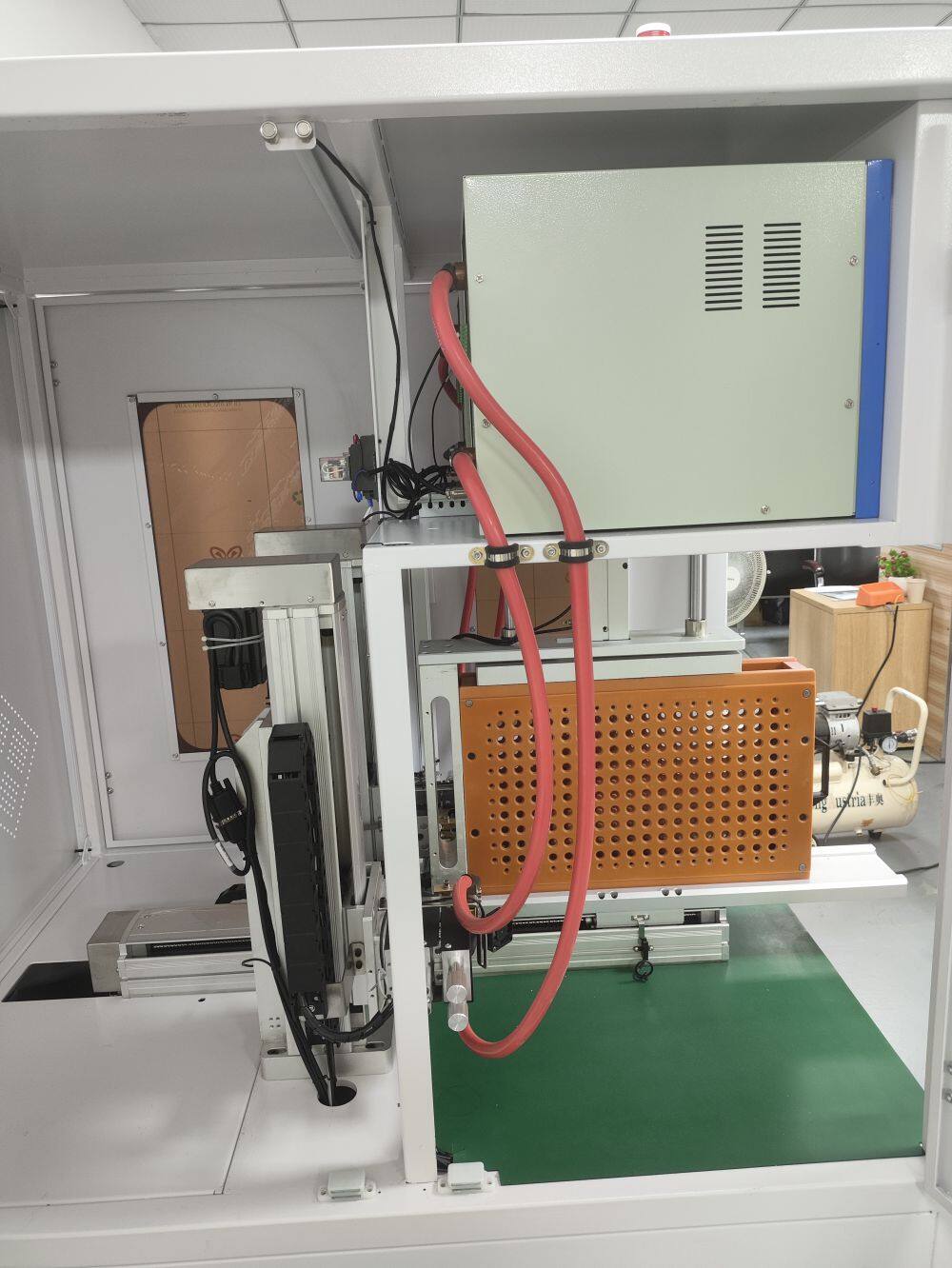

Precise Discharge: When triggered, the energy is released in a controlled DC pulse—short duration (usually milliseconds, ms) but high current density.

Weld Formation: The DC pulse heats the lithium battery tabs (typically nickel-plated steel, pure nickel, or aluminum) and electrodes rapidly, forming a stable weld before heat spreads to the battery cell (which is sensitive to high temperatures).

Key Feature: Relies on stored energy and DC pulse discharge for ultra-precise current control.

1.2 AC Spot Welder (Traditional Industrial Type)

This is a classic, low-cost welding device designed for general metal welding. Its principle is simpler:

Direct AC Use: It draws 220V or 380V AC mains directly, without energy storage components.

Transformer Step-Down: A large transformer reduces the high-voltage AC to low-voltage (usually 1-10V) but high-current (hundreds to thousands of amps) AC.

AC Discharge: The low-voltage AC current flows through the electrodes and workpiece, generating heat via electrical resistance to melt the metal.

Weld Formation: Heat accumulates during the AC cycle (50/60Hz, so each cycle is ~16-20ms), forming a weld after a few cycles.

Key Feature: Relies on mains AC current with longer, less controllable discharge durations.

2. Application Scenarios: Which Fits Your Needs?

The two welders are designed for entirely different use cases—this is the most critical factor for beginners choosing AITOP equipment.

2.1 Lithium Battery Storage Spot Welder: Specialized for Lithium Batteries

Its precision and low heat output make it the only safe choice for lithium battery assembly/maintenance, which is AITOP’s core application scenario. It is ideal for:

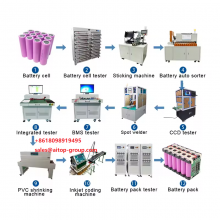

Lithium battery pack assembly: Welding tabs (nickel, nickel-plated steel) to 18650, 21700, or prismatic lithium battery cells (e.g., for power tools, electric vehicles, solar energy storage systems).

Small electronic devices: Repairing lithium battery packs for smartphones, laptops, or drones (where cells are tiny and heat-sensitive).

Low-volume to medium-volume production: Hobbyists, workshops, or small factories focused on lithium battery products (AITOP’s entry-level models cater to hobbyists, while industrial models serve workshops).

Why not use AC welders here? Lithium battery cells are EASY damaged by overheating—AC welders generate prolonged heat, which can cause cell swelling, leakage, or even fire/explosion.

2.2 AC Spot Welder: For General Industrial Metal Welding

It is a workhorse for thick, heat-resistant metals but unsafe for lithium batteries. Common applications include:

Automotive repair: Welding sheet metal (e.g., car body panels, exhaust parts) or steel wire meshes.

Hardware manufacturing: Joining iron, steel, or stainless steel components (e.g., hinges, brackets).

Low-precision metalwork: Welding thick (≥0.5mm) non-heat-sensitive metals where weld appearance is not critical.

Why not use it for lithium batteries? Poor current control leads to uneven heat distribution—tabs may burn through, or cells may be damaged.

3. Performance Comparison: A Side-by-Side Breakdown

For beginners, performance metrics directly affect usability, safety, and weld quality. Below is a comparison tailored to AITOP’s target users (lithium battery enthusiasts/workshops):

4. How Beginners Choose: AITOP Equipment Selection Tips

If your goal is lithium battery-related work (the most common scenario for AITOP users), the choice is clear—but you still need to pick the right model based on your needs:

Step 1: Confirm Your Core Task

Hobby/DIY (e.g., making small battery packs for drones): Choose AITOP’s entry-level handheld lithium battery spot welder (e.g., models with 100-150A current, built-in battery). It’s portable, affordable, and easy to operate.

Workshop/medium production (e.g., assembling 12V/24V storage battery packs): Opt for AITOP’s desktop lithium battery spot welder (200-300A current, AC-powered, with digital controls). It balances efficiency and precision.

General metal welding (no lithium batteries): An AC spot welder is sufficient—but note that AITOP focuses on lithium battery equipment, so you may need to look for other brands.

Step 2: Key Metrics to Check

Current range: For 18650 cells, 80-150A is enough; for thicker prismatic cells, choose 200A+ (AITOP’s product pages clearly mark this).

Energy storage type: Capacitor-based models charge faster; lithium battery-based models are more portable—pick based on your work environment.

Safety features: Ensure the model has overcurrent protection and electrode overheating alarms (standard on AITOP’s products).

5. Final Verdict: Lithium Battery Work = Choose AITOP’s Specialized Welder

For beginners targeting lithium battery assembly or repair:

Never use an AC spot welder—it risks damaging batteries and personal safety.

Lithium battery storage spot welders (AITOP’s core line) are the only reliable option, thanks to their precision, low heat, and safety features.

4. How Beginners Choose: AITOP Equipment Selection TipsStep 1: Confirm Your Core TaskStep 2: Key Metrics to Check5. Final Verdict: Lithium Battery Work = Choose AITOP’s Specialized Welder

4. How Beginners Choose: AITOP Equipment Selection TipsStep 1: Confirm Your Core TaskStep 2: Key Metrics to Check5. Final Verdict: Lithium Battery Work = Choose AITOP’s Specialized Welder

4. How Beginners Choose: AITOP Equipment Selection TipsStep 1: Confirm Your Core TaskStep 2: Key Metrics to Check5. Final Verdict: Lithium Battery Work = Choose AITOP’s Specialized Welder

4. How Beginners Choose: AITOP Equipment Selection TipsStep 1: Confirm Your Core TaskStep 2: Key Metrics to Check5. Final Verdict: Lithium Battery Work = Choose AITOP’s Specialized Welder Read More

Read More Read More

Read More Read More

Read More Read More

Read More