Automatic ESS Prismatic Lithium Battery Pack Assembly Line

Automatic Prismatic Lithium Battery Pack Assembly Line

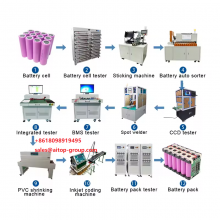

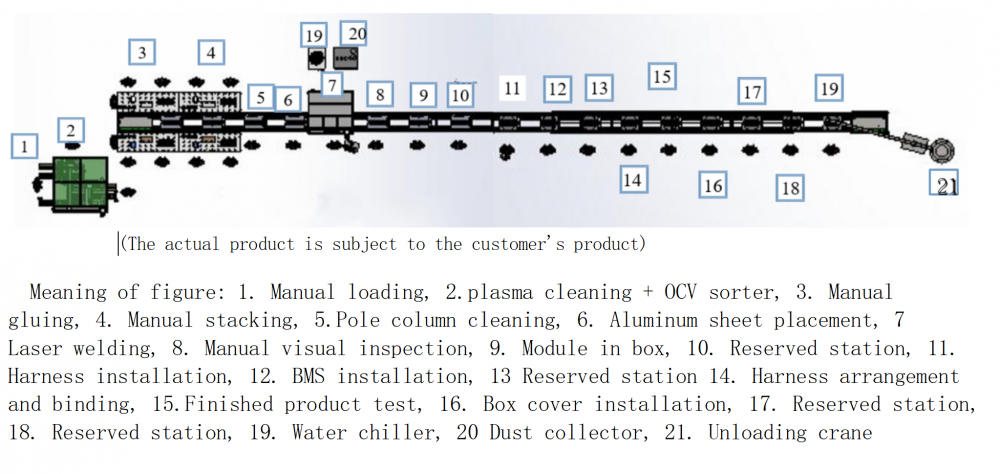

production process requirements and workshop layout, custom-made combined square shell lithium battery energy storage PACK module automatic production line, the design structure of this line is reasonable and compatible, and is suitable for batteries of different sizes and specifications Module production; The project plan is independently developed and designed by our team, processed and assembled, commissioned and trained for after-sales service. The whole line adopts a modular design and consists of the following functional areas - feeding and sorting, gluing of assembled frames, manual stacking, extrusion and binding, Binding scan code, polarity detection, pole cleaning, connection bar placement, connection bar welding, acquisition line welding, packing, cover locking screw, EOL test, double-speed chain circulation line, tooling fixture, bad removal, manual off-line Composition of other organization workstations

For its yield rate, its requirements for incoming materials: so module nesting materials (end plates, brackets, adhesive tape, batteries, etc.) are guaranteed to require consistency.

Introduction to Mechanism Module Functions——Double speed chain body tooling

Main functions of the equipment:

This module mainly realizes the automatic circulation of tooling pallets, and is composed of elevator/double-speed chain main body/tooling mechanism/blocking mechanism

The load is greater than 150KG, each blocking stop position can be released automatically or manually activated by the button

Introduction to Mechanism Module Functions——OCV test sorting

Module function introduction:

This module mainly uses high-precision testing instruments to complete the classification and data recording of the voltage internal resistance test of the square shell cell Through manual picking and loading, the belt transports the batteries to the area to be tested. First, a high-definition identification code reader reads the identity code of the battery, and then completes the OCV test and matches the data with the battery code to save or transmit. The test value is within the range The batteries are picked up by the manipulator and transported to different gears to flow out. If the test exceeds the set value, they will be moved to the NG channel. When the OK channel is full of 8 batteries, they will be loaded into the buffer box by the manipulator, and the belt conveyor will be sent to the adhesive. Stacking position to complete the next process

Functional advantages:

1. The condition value of test parameters can be set on the man-machine interface.

2. The probe adopts nickel-plated probe assembly, and the four-wire method is used for testing. The probe is cylindrical and the bottom of the probe is sharp, which can be well adapted to ensure Contact, nickel-plated probe process, greatly reduces impedance, improves test accuracy.

3. The battery performance data of the system test implements the database management mode, long-term storage, strong traceability, with the data analysis function of the software, the product Conduct long-term monitoring and analysis of performance and quality to guide the improvement of R&D formulas and improve the production process.

4. The mechanical gripper is designed to prevent slipping and pinching. Effectively protect the battery cells,

5. Prevent mistaking and matching groups due to personnel mistakes, increase the frame buffer design to prevent fooling,

6. The equipment is easy to operate, convenient to debug, and stable in performance.

Introduction to Mechanism Module Functions——OCV test sorting

Mechanism Module Functions——Laser welding of positive and negative pole aluminum sheet of PACK

Laser welding machine indicators:

1) Welding thickness 0.5-3mm (adjustable);

2) Travel range: 800*400*300mm;

3) Welding speed: 10mm/s (adjustable);

4) Laser type: continuous;

5) Laser power: 3kw (adjustable);

6) Galvanometer spot: center spot 0.15mm;

7) Equipped with air knife dust removal;

8) Laser working medium: optical fiber;

9) Laser service life: ≥5 years;

10) If the equipment needs to run automatically across the double-speed chain body, the net width of the double-speed chain body is 850mm, and the net height is 750mm (from the ground to the highest point of the double-speed chain body), and the line body has its own positioning extension (with 4 positioning columns)

Introduction to Mechanism Module Functions——EOL test

Recently Posted

-

Which is the necessary materials and machine for assembly drone battery pack from AITOP group

December 17, 2025Which is the necessary materials and machine for assembly drone battery pack from AITOP groupThe main equipment of cylindrical lit Read More

Read More -

AITOP | High-Efficiency Battery Pack Assembly Lines for E2W & E3W Vehicles &drone battery

December 17, 2025AITOP | High-Efficiency Battery Pack Assembly Lines for E2W & E3W VehiclesPower the electric mobility revolution with precisio Read More

Read More -

21700 18650 32650 Lithium Ion Battery Pack Assembly Line

October 8, 2025Lithium Ion Battery Pack Assembly LineProducts Description Lithium ion Battery Pack Assembly Line is mainly to process batter Read More

Read More -

Why UAV Drone Batteries Demand AITOP’s Professional Equipment: Ensuring Production & Quality Excelle

September 26, 2025In the booming global UAV market—where consumer drones capture stunning aerial views, agricultural drones boost crop yields, and i Read More

Read More