Why need Regenerative Battery Pack Testing tester System

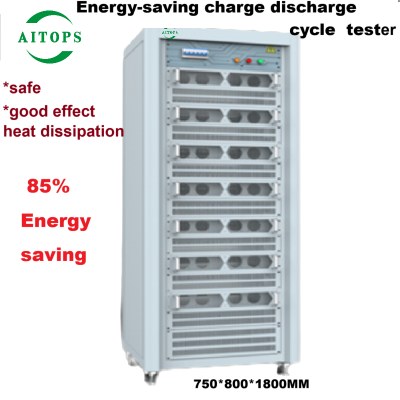

100V 100A Regenerative Battery Pack Test System

This high-precision test system is engineered for cyclic life testing and quality validation of lithium-ion, lead-acid, Ni-Cd, and NiMH battery packs. Featuring bidirectional energy feedback (regeneration), it recycles discharge energy back to the grid with >95% efficiency, cutting operational costs and heat generation. Designed for production lines and R&D labs, it supports CC/CV/CP modes, 1ms response time, and 0.05% FS accuracy. Ideal for EV, storage, and power-tool batteries, ensuring IEC 62660 compliance.

- Regenerative Efficiency: >95% energy feedback to grid.

- Voltage/Current Range: 0-100V, ±100A (bidirectional).

- Test Modes: Cycle life, capacity, HPPC, pulse testing.

- Safety: Over-voltage, reverse polarity, thermal protection.

- Software: Automated scripting, real-time analytics, CAN/RS485 integration.

Advantages Power feedback to grid with direct current bus efficiency ≥90%: Both charging and discharging is energy-saving which saves a lot of electric power expenses and air-conditioner fees. CCCV charge: CC charge transfer to CV charge smoothly, without any impact, which can avoid the micro-shot circuit due to high temperature of peak current impact or to avoid PCB protection or second protection action caused by over-charging. Current and voltage sampling is of high stability and accuracy: this equipment applied 16bit bipolar ADC/DAC unit, to ensure voltage sampling high accuracy and long-term stability. User management includes authority management, role management and user management. Managers can set management permissions for each function module of the software, and set multiple user IDs according to the operator's permission requirements. DCIR: four DCIR test schemes are supported to meet different test requirements. Voltage clamp function: when battery does protect action through charging process, voltage clamp to pre-set voltage can protect battery or PCB from damage. The recording conditions can be set by sections in the test step, and the intelligent data management record can be implemented. Each channel has a built-in CAN and RS485 communication module to support BMS CAN communication function: collect the total voltage, total current, single cell voltage, temperature and other data of BMS system in real time, and make synchronous comparison with CDS voltage and current data. When setting BMS voltage, current, temperature and other data to a certain condition, the main channel steps will stop or convert, and the specific reading information will be provided by the customer. Support one click DBC import and manual customization of BMS protocol functions, and support sampling different BMS protocols for each channel. It supports user-defined signal sets. Users can customize the setting name according to their own needs and data recording requirements. Working Environment and Technical Parameters Power supply: AC 380V±10%, frequency: 50HZ±10%. Maximum input power of the whole cabinet: 44.4 kW (4CHS) Working temperature: 0℃ - 45℃. Humidity: less than ≤ 95%R.H (non-condensing). No severe shake, no corrosive gases, no flammable or explosive gases around. Resolution: AD 16 bit.

Advantages Power feedback to grid with direct current bus efficiency ≥90%: Both charging and discharging is energy-saving which saves a lot of electric power expenses and air-conditioner fees. CCCV charge: CC charge transfer to CV charge smoothly, without any impact, which can avoid the micro-shot circuit due to high temperature of peak current impact or to avoid PCB protection or second protection action caused by over-charging. Current and voltage sampling is of high stability and accuracy: this equipment applied 16bit bipolar ADC/DAC unit, to ensure voltage sampling high accuracy and long-term stability. User management includes authority management, role management and user management. Managers can set management permissions for each function module of the software, and set multiple user IDs according to the operator's permission requirements. DCIR: four DCIR test schemes are supported to meet different test requirements. Voltage clamp function: when battery does protect action through charging process, voltage clamp to pre-set voltage can protect battery or PCB from damage. The recording conditions can be set by sections in the test step, and the intelligent data management record can be implemented. Each channel has a built-in CAN and RS485 communication module to support BMS CAN communication function: collect the total voltage, total current, single cell voltage, temperature and other data of BMS system in real time, and make synchronous comparison with CDS voltage and current data. When setting BMS voltage, current, temperature and other data to a certain condition, the main channel steps will stop or convert, and the specific reading information will be provided by the customer. Support one click DBC import and manual customization of BMS protocol functions, and support sampling different BMS protocols for each channel. It supports user-defined signal sets. Users can customize the setting name according to their own needs and data recording requirements. Working Environment and Technical Parameters Power supply: AC 380V±10%, frequency: 50HZ±10%. Maximum input power of the whole cabinet: 44.4 kW (4CHS) Working temperature: 0℃ - 45℃. Humidity: less than ≤ 95%R.H (non-condensing). No severe shake, no corrosive gases, no flammable or explosive gases around. Resolution: AD 16 bit.

Recently Posted

-

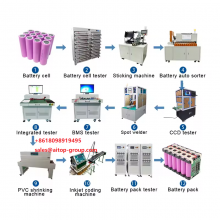

Which is the necessary materials and machine for assembly drone battery pack from AITOP group

December 17, 2025Which is the necessary materials and machine for assembly drone battery pack from AITOP groupThe main equipment of cylindrical lit Read More

Read More -

AITOP | High-Efficiency Battery Pack Assembly Lines for E2W & E3W Vehicles &drone battery

December 17, 2025AITOP | High-Efficiency Battery Pack Assembly Lines for E2W & E3W VehiclesPower the electric mobility revolution with precisio Read More

Read More -

21700 18650 32650 Lithium Ion Battery Pack Assembly Line

October 8, 2025Lithium Ion Battery Pack Assembly LineProducts Description Lithium ion Battery Pack Assembly Line is mainly to process batter Read More

Read More -

Automatic ESS Prismatic Lithium Battery Pack Assembly Line

October 8, 2025Automatic Prismatic Lithium Battery Pack Assembly Lineproduction process requirements and workshop layout, custom-made combined sq Read More

Read More