Home > Company News > Why CCD inspection machine for battery pack important to testing

Company News

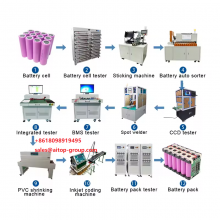

Why important CCD inspection machine for battery testing ?

Why CCD Detection Equipment is Very Important in the Production of Lithium Battery Packs?

In the production of lithium battery packs, CCD detection equipment plays a crucial role for the following reasons:

Firstly, it can accurately detect various defects and abnormalities on the surface of lithium battery cells, such as scratches, dents, and foreign matter. This helps to ensure the quality and integrity of the battery cells and reduces the risk of potential safety hazards.

Secondly, CCD detection equipment can precisely measure the dimensions and geometries of the battery cells, ensuring that they meet the required specifications. This is essential for the proper assembly and performance of the lithium battery pack.

Moreover, it can monitor the consistency and uniformity of the battery cells, helping to identify any inconsistent or substandard cells that might affect the overall performance and lifespan of the battery pack.

It also enables real-time detection and feedback, allowing for immediate adjustments and improvements in the production process to maintain high quality standards.

Furthermore, with the increasing demand for high-quality and reliable lithium battery packs in various industries, CCD detection equipment provides an effective means to ensure the quality and reliability of the final products, enhancing the competitiveness of the manufacturers.

In summary, CCD detection equipment is of great significance in the production of lithium battery packs, as it helps to guarantee the quality, performance, and safety of the batteries, and promotes the development and application of the lithium battery industry.

CCD detection system

--- CCD Testing Machine

---Battery CCD Testing Machine

1. Function description

CCD detector is an automatic equipment for lithium battery processing, which has the function of automatically detecting the positive and negative poles of lithium battery cylindrical cells.

2. Process flow

The cell enters the detection area → sampling and scanning → positive and negative electrode detection → ng automatic detection → OK

3. Technical parameters of equipment

Specifications AITOP-CCD001

XY axis stroke 500mm (customizable)

Motor transmission speed 300mm/S

operating system Industrial computer smart camera

Detection method Single machine detection

Repeat positioning accuracy ±0.1mm

detection efficiency 1s /pcs

Overall power 500W

Machine weight 150KG

Maximum bearing weight 60KG

Input power supply Single phase AC 220v/50hz

Overall dimension 860*630*1630mm

4. Equipment configuration list

● display: Philips

● industrial computer: Microcomputer

● switching power supply: Taiwan Mingwei

5. Operating environment

1) Indoor temperature: -30 ℃ ~50 ℃.

2) Indoor humidity: below 55%.

3) Factory site: no pollution, no strong electromagnetic interference.

6. Random data

1) Equipment operation manual

2) List of vulnerable parts: 1 copy

3) A set of random tools

TOP Battery machine factory contact number

Shenzhen AITOP Intelligent Equipment Co., Ltd.

Email :sales(@)aitop-group.com /leon(@)aitop-group.com

wehcat/whatsapp /Phone :008618520989583/008618435204981/18098989643

8618820281861/ 8618098919495